PARP & Innovation Norway & BSSC: Zero-emission technologies in maritime economy conference – Part 2

Seminar session (part 2): ZERO-EMISSION BLUE ECONOMY

With the support of the Baltic Sea and Space Cluster, The Polish Agency for Enterprise Development and Innovation Norway organized study trip in the Port of Gdynia.

Presentations onboard the vessel during the study trip in the Port of Gdynia, BSSC Memebers: Marek Grzybowski, President, Baltic Sea & Space Cluster; prof. Andrzej Stateczny, CEO, Marine Technology; Żaneta Milewska, Director, Development Department, Port of Gdańsk Authority; Jacek Milewski, Finance Director, Memebr of the Board, CRIST, Coordinator of the BSSC ZEV HUB – Zero-Emmision Vessel Production HUB.

President Marek Grzybowski presented information about the Polish Maritime Cluster – activities for the green transformation: production, services, science and maritime education for a green economy.

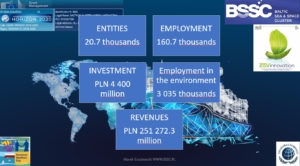

– 20.7 thousands entities are in the Polish Maritime Industry with direct , employment 160.7 thousands and indirect 3 035 thousands employment. Polish Maritime Industry with the revenues abot pln 251 272.3 million in 2022. The Polish Maritime Business invested about pln 4 400 million in 2022 – informed President Marek Grzybowski.

The Polish Maritime Cluster includes ports, production and repair shipyards, Marine fisheries and maritime manufacturing, shipping, scientific and research institutes, certification institutes, universities and vocational schools, production and service plants, including those related to tourism and offshore wind energy. An important part of the Polish Maritime Cluster is the Baltic Sea and Space Cluster.

The BSS Cluster Pentagon Helix HUB integrates the transfer of knowledge between science and business, supports social initiatives, local governments and administration, develops investor relations in the maritime and space industry. BSSC integrates technological, legal and economic solutions at the scientific, business and social level. Today the cluster develops in the Pentagon Helix formula, integrating the transfer of knowledge between science and business, supporting social initiatives, local government and administration, developing investor relations. Today the cluster’s activity is characterized by a holistic, integrative and global approach, making the activity of maritime industries part of Economy 4.0.

Within the „Cluster” there are currently six Hubs: ICT & AI, construction of zero-emission ships – ZEVInnovation, design and construction of installations producing green energy – GreenTech, scientific-research, legal-financial and educational. All hubs bring together around 60 companies, research centers and R&D units. Within the „Cluster” Hubs, i.e. highly specialized small clusters, operate successfully, a type of consortia. Within them, tasks are carried out in a specific field and professional activity. In other words, a team of experts from a given hub is responsible for issues it knows best.

Baltic Sea and Space Cluster specialized research teams operate within six Hubs, which brings together 60 Polish innovative companies.

There are currently six Hubs: ICT & AI, construction of zero-emission ships – ZEVInnovation, design and construction of installations producing green energy – GreenTech, scientific-research, legal-financial and educational. All hubs bring together around 60 companies, research centers and R&D units. They cooperate with a group of approximately 2,300 cooperators, companies specializing in the design and implementation of innovative marine and space technologies, research and development, education and professional training for maritime industries.

BSSC is a cluster of international projects. The cluster implements, among others: projects from Horizon 2020 (Galatea, Space Academy, SEA EU – partership). 2 project from Norway Grants are in progress.

Info about ZEV Innovation project:

„Monitoring and Observation System for Port Areas Using Floating Unmanned Mobile Research Platforms” is a project by the Port of Gdynia Authority, in which Marine Technlogy performs important tasks related to research in the port’s water areas – said Prof. Andrzej Stateczny.

The Marine Technology company, as a result of the completed tender, was selected to perform the contract for services related to research and measurements via an unmanned unit for the project with the acronym MPSS. The project is also the first project implemented by the Port of Gdynia Authority SA. with the support of funds that come from the funds of the Norwegian mechanism in the current perspective.

The aim of the MPSS project is to identify the possibilities for the accreditation of tests with water-based platforms and to provide recommendations for the unification of technical standards in this field.

Task 1: Performing hydrographic measurements: bathymetric measurements and sonar surveys in the indicated port waters.

Task 2: Automatic sampling of water (surface and deep seabed) and bottom sediments at designated measuring points and measurements made with the use of a plankton grid at any time of the year.

The project consists of the use of a mobile research platform for the Port of Gdynia and includes two very important tasks to be completed by 31 December 2023 – informed Prof. Andrzej Stateczny. In March, April and May, bathymetric and sonar measurements were made along the following quays: Czech, Finnish, Rotterdam, Rumuński, Słowacki, United States and Hungarian. The documentation was delivered to the Port of Gdynia Authority SA.

More about the Project from Norway Grants:

https://www.bssc.pl/2023/05/20/port-of-gdynia-uses-hydrodrones-to-survey-the-port-basins/

– The quays at the Port of Gdynia are abot 18 km long, of which over 11 km are used for handling operations. The total area of the port is more than : 970 hectares, including the land area of about 620 hectares – informed President Marek Grzybowski. The Port of Gdynia operates 24 hours a day.

The Port of Gdynia is a modern universal port. Two terminals specializing in handling general cargo in containers. The port has the newest ferry terminal in the Baltic Sea with an OPS – onshore connection to power ships with electricity. Stena Line Polska introduced two innovative ferries with dual fuel engines to the Gdynia – Karlskrona service. Ships can sail for 11 hours. on electric motors. Stena Line Polska and FInnlines (Gdynia – FInlandia service) provide ro-ro cargo transport. At the port, non-containerized general cargo is loaded, such as steel, baled paper from Finland and wood from Sweden.

– An important cargo at the port is arms imported from South Korea. Military equipment of the US army and other NATO countries stationed in Poland or exercising on training grounds is also unloaded in Gdynia – informed President Marek Grzybowski. Bulk cargo is also transhipped in Gdynia, including coal, grain, feed and artificial fertilizers. The liquid cargo terminal transships imported fuels.

In the port of Gdynia, many quays were modernized, the port was deepened, the internal entrance was widened, a 400 m long turntable for ships was built, and the construction of an external port for mooring large container ships, passenger ships and other ships is planned – adds Grzybowski.

Director Żaneta Milewska presented a film about the development of the Port of Gdańsk and planned investments.

Port of Gdańsk Authority S.A. is seeking funding for the project “Improving the Port of Gdańsk infrastructure with an analysis of the implementation of a low-carbon OPS system for the TEN-T network sustainable development”, under the “Connecting Europe” Facility for 2021–2027 (CEF 2). This investment includes the development of four more Inner Harbour wharves, with a total length of 1,916 meters, along with suitable rail infrastructure. Wiślane and Bytomskie Quays are located along the Port Channel, while Rudowe III and partially Węglowe Quays are located in the Górniczy Basin.

Port of Gdańsk Authority S.A. announced three tender procedures for the selection of contractors for construction works on the Quays: Rudowe, Bytomskie and Wiślane. The announcement of the fourth tender, for the Węglowe Quay, is planned for the third quarter of 2023. A study task is also planned as part of the project, concerning the preparation of the “Analysis of the implementation of the onshore power supply system for ships in the Port of Gdańsk (OPS – Onshore Power Supply)”. The study is to include an analysis of the state of application of OPS systems for supplying ships with 100 kW electricity during their berth in seaports; assessment of the state of adaptation of sea vessels to shore-side electricity supplies for vessels; assessment of the demand for powering ships at the Port of Gdańsk and recommendations for the implementation of this technology at the Port of Gdańsk. The planned investment implementation period is 2023–2027.

The construction of T3 is stared in Baltic Hub, Port Gdańsk container terminal. The bigest container terminal in Blatic Sea. The construction is divided into two stages. Budimex and DEME consortium will build a 36-hectare platform adjacent to Terminal 1 (T1). In the second stage, the construction of a quay wall with a length of 717 m and a depth of 17.5 m will begin. The work should be completed in the second quarter of 2025. After completing the investment, the Port of Gdansk will be able to tranship 4.5 million TEU.

– CRIST Shipyad occupies over 28 ha adjacent to the port of Gdynia. As a relatively warm area, ice-free harbor waters, with good navigation conditions and with almost no tidal effects, it is easily accessible from the Atlantic through the Baltic sea – says director Jacek Milewski, BSSC ZEV HUB Coordinator. The production processes are performed in 4 production halls with 61 gantry cranes and portal cranes with a lifting capacity of up to 120 tons.

Currently, CRIST is implementing 12 innovative projects. MPP special pontoon was transferred to the shipowner 2 days ago. Vessel is mooring the CRIST quay.

The international consortium Femern Link Contractors ordered a pontoon at the shipyard. The consortium is implementing a project to build an 18-km Femern Link tunnel, connecting the German E47 in Fehrman with the Danish E47 IN Rødbyhavn on the island of Lolland. MPP has a device for spreading gravel to the seabed. The ship and device were built at the CRIST shipyard. StoGda supported CRIST and developed the design to the Detail Design phase and provided complete Workshop Documentation. The gravel spreading device is remotely controlled. The device is lowered under the hull of the barge to 46 meters below the waterline. The MPP hull is 130 meters long. The entire unit with the transmission equipment is 149 meters long. There will be 14,000 in two cargo compartments. tons of gravel.

– ZEV Innovation is an international project that is to create a group of companies, entities, institutions, organizations from Poland, Norway and Croatia that will associate both enterprises and institutions from the business environment, which will deal with the actual creation from design through construction, through even operation of zero-emission ships for a specific target group – informed Marek Grzybowski. This hub for the production of zero-emission ships, where Crist is the main coordinator, will participate in the project and the hub will carry out the order for the creation of the entire ship – emphasized Jacek Milewski.

CRIST is a leading shipyard on the European market. CRIST’s specialty is shipbuilding and marine constructions. It is one of the leaders in the offshore and hybrid ships industry. He successfully implements more and more advanced projects. CRIST has delivered vessels such as “Electra”, Heavy Maintenance Vessel “VIDAR”, Heavy Lift Jack – Up Vessel “INNOVATION” and Jack-up Barge “THOR”. CRIST has been combining innovation with experience for over 3 decades, informed Jacek Milewski. Baltic ZEV HUB manager – informed Milewski

During the journey we pass PGZ Stocznia Wojenna. We see the construction of the hall. The shipyard is preparing to build frigates for the Polish Navy under the “Miecznik” program. The frigate construction consortium includes Babcock, PGZ Stocznia Wojenna and Remontowa Shipbuilding.

The ship “Rubin” passes the Nauta Remontowa Shipyard. There are ships in floating docks and at quays. Renovations are being carried out on ships, and new ballast water purification devices are being installed. Hull cleaning is being carried out. Ships are painted.

The business mixer on the ship and in the Mondo di Vinegre restaurant in Gdynia took place after the trip.